OVERVIEW OF KROLL & ZILLER (K & Z)

The Ziller Holding Company was established in 1926 in Hilden Germany, near Dusseldorf by Dr. Hans Ziller. The holding group consists of Nilos Ring, Nilos Belting, Kroll & Ziller Gaskets and Coal Control.

Kroll & Ziller is the market leader in the Rubber – Steel Gaskets market

- Kroll & Ziller flange gaskets are made of elastomer materials with a steel insert.

- The K & Z Rubber–Steel flange gaskets and adjustable Wedge Rings have been proven in use over many years and in all areas of pipeline construction.

- Several top steel mills, power plants, petrochemical industries, pharmaceutical industries as well as gas and water companies are long-time users of K & Z’s sealing products.

K & Z is built on the following tenets:

- Environmentally Safe Gaskets – approved by independent bodies.

- Operating Reliability – minimizes daily problems of the maintenance staff and fitters.

- Standardization – allows for a substantive reduction of variety and inventory.

- Easy Handling – minimizes daily problems of the maintenance staff and fitters.

- Cost Effective Logistics – minimizes problems for procurement managers and buyers.

PRODUCT OFFERINGS

- G-ST and G-ST-P/S profile flange gaskets made of elastomer materials with steel insert.

- G-ST Wedge Rings (infinitely variable from 0 to 8 degrees)

- TEFMET PTFE flat gaskets

- Kammprofile gaskets

THE KROLL & ZILLER GASKETS GUARANTEE

- High efficiency due to reduced operating costs.

- Reduced fugitive emissions.

- Ease of installation is attributed to the rigid steel core.

- The policy of Kroll-Ziller over the last 15 years has been specialization, research and development in close collaboration with a large number of customers.

COMBINATION OF FACTORS WHY KROLL & ZILLER G-ST GASKETS ARE IDEAL

- Vulcanization provides an extremely good adhesion between the steel insert and the rubber sheath ensuring separations and blowouts are not possible.

- Optimum handling during installation due to the rigid steel core.

- Ring style gasket ensures self centering on the bolt circle.

THE NEW GENERATION OF SEALING

- The O – Ring is the most static sealing element.

- The performance is perfect even without a cost intensive groove.

- The rigid body of the profile G-ST gaskets absorbs high surface pressures.

- Offers a degree of operating reliability.

- Offers advantages like wide sealing surface area and rectangular instead of round cross section near the O-Ring.

BENEFITS LINKED TO G-ST-P GASKET APPLICATIONS

- Sealing under minimum bolt tightening

- Compensation of surface imperfections

- Flange and bolt designs can be more lightweight

- Higher durability of plastic flange joints

- Angle differences are more easily compensated compared to simple flat gaskets

- Expensive machining of an O-ring groove on the flange is unnecessary

TYPES OF FLANGE GASKETS & USES

G-ST Flange Gaskets

- Flat rubber/steel gaskets

G-ST-P/S

- For various applications best suited for joints connecting non-metallic (plastics, GRP, PVC, PP< PE, PVDF, etc.) and steel flanges.

G-ST-P/KN

- For various applications best suited for partially coated flanges and heavy duty services.

- Also suitable for non load bearing flange joints

G-ST-P/OE

- Flexible design gasket with visible stainless steel insert.

G-ST-WEDGE RINGS

- Ideally suited for solving alignment problems during assembly or for filling large gaps in installation.

TEFMET GASKETS

TEFMET gaskets are made of Polytetrafluoroethylene PTFE with a perforated stainless steel insert

- Have a high chemical resistance.

- For pressures up to 400 psi. (25 bar)

- Temperature range from 212F to 446F (100C to 230C)

- Made from Dyneon TFM 1600 with AISI 304 SS (1.4301)

- Resistant to nearly every media within the entire temperature range

- Minimal creep and cold flow characteristic even at high pressure and temperature because of the perforated SS insert

- gas tight

- simple and safe assembly

- blow-out safe due to SS insert

KAMMPROFILE GASKETS

KAMMPROFILE GASKETS

Kammprofile gaskets are available in a large number of alloys and soft facing materials.

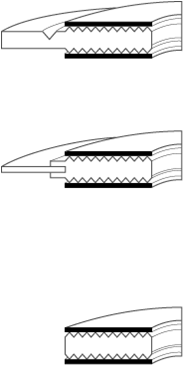

- Thrust ring with kammprofile on both sides, graduation 1 mm / .04 inch with fixed centering ring and rated breaking zone. For flanges with flat or raised face.

- standard design

- slim design

- Thrust ring with kammprofile on both sides, graduation 1 mm / .04 inch with loose centering ring. For flanges with flat face.

- The separation of thrust ring and centering ring assures a high safety during operation, also under extreme conditions (no sudden breakdown caused by vibration failure or thermal stress)

- Thrust ring with kammprofile on both sides,graduation 1 mm / .04 inch without centering ring.

- For flanges with tongue / groove or groove / groove facings.*

KAMMPROFILE PROPERTIES AND APPLICATIONS

Excellent temperature resistance.

- Usage at high pressure possible. Full utilization of bolt forces recommended.

- Very good resistance against nearly all kind of media, especially against corrosives.

- Heavy duty, reinforced and blow-out safe gaskets with high operation reliability.

- Very low leakage rates with gases and liquids. Fulfills high sealing requirements.

- No aging and embrittlement even at high temperatures.

- Asbestos-free, completely harmless to health. Can be reused after re-lamination.

- Very good handling at transport, installation and deinstallation. Solid state design.

- No destruction through bolt overload. Marking of each gasket on centering ring.

- Usage of low chloride graphite layers and adhesive allows usage in systems made of austenitic steel.

- Are well established in chemical and petrochemical industries; in conventional and nuclear power plants.

KROLL & ZILLER PDF Catalog

![]() CLICK HERE to download the complete Kroll & Ziller catalog in pdf format.

CLICK HERE to download the complete Kroll & Ziller catalog in pdf format.

Material Selections:

Kroll & Ziller’s G-ST line comes in a variety of materials to suit almost any need.

- FPM-S – Temp. tmax. -4 to +392 degrees F, Shore -A-hardness 80 (+/-5)

- EPDM – Temp. tmax. -22 to +248 degrees F, Shore -A-hardness 70 (+/-5), FDA Approved

- NBR – Temp. tmax. -13 to +158 degrees F, Shore -A-hardness 80 (+/-5), FDA Approved

- HNBR – Temp. tmax. -4 to +302 degrees F, Shore -A-hardness 75 (+/-5)

- CSM – Temp. tmax. -4 to +248 degrees F, Shore -A-hardness 70 (+/-5)

- NR – Temp. tmax. -13 to +158 degrees F, Shore -A-hardness 60 (+/-5

- IIR – Temp. tmax. -13 to +248 degrees F, Shore -A-hardness 55 (+/-5)

- CR – Temp. tmax. -13 to +203 degrees F, Shore -A-hardness 63 (+/-5)